Table of Contents

Benefits of Using Stainless Steel G277 Eye Bolt Castings in Rigging Applications

Rigging is an essential component in various industries, including construction, maritime, and entertainment. It involves the use of ropes, cables, and hardware to lift and move heavy objects safely and efficiently. One crucial element in rigging is the eye bolt, which is used to secure ropes or cables to a structure or object. Eye bolts come in various materials, but stainless steel G277 eye bolt castings are increasingly being used for their superior strength and durability.

Stainless steel G277 eye bolt castings are made from a specific grade of stainless steel known for its high tensile strength and corrosion resistance. This makes them ideal for use in rigging applications where strength and durability are paramount. The G277 designation indicates that the eye bolt meets specific standards for strength and performance, ensuring that it can withstand the rigors of heavy lifting and moving.

One of the key benefits of using stainless steel G277 eye bolt castings in rigging applications is their superior strength. Stainless steel is known for its high tensile strength, which means it can withstand heavy loads without deforming or breaking. This is crucial in rigging, where safety is paramount, and failure of a component can have catastrophic consequences. By using stainless steel G277 eye bolt castings, riggers can have confidence that their equipment can handle the loads they are subjected to.

In addition to their strength, stainless steel G277 eye bolt castings are also highly resistant to corrosion. This is important in rigging applications where the equipment is often exposed to harsh environments, such as saltwater or chemicals. Corrosion can weaken metal components over time, leading to failure and potentially dangerous situations. By using stainless steel G277 eye bolt castings, riggers can ensure that their equipment will remain strong and reliable even in challenging conditions.

Another benefit of using stainless steel G277 eye bolt castings in rigging applications is their versatility. Stainless steel is a versatile material that can be easily machined and formed into complex shapes, making it ideal for custom rigging applications. Eye bolt castings can be designed to specific specifications, allowing riggers to create custom solutions for their lifting and moving needs. This flexibility is essential in industries where standard off-the-shelf components may not be suitable for the job at hand.

In conclusion, stainless steel G277 eye bolt castings offer a range of benefits for rigging applications. Their superior strength, corrosion resistance, and versatility make them an ideal choice for industries where safety and reliability are paramount. By using stainless steel G277 eye bolt castings, riggers can ensure that their equipment can handle the demands of heavy lifting and moving, even in challenging environments. With their proven performance and durability, stainless steel G277 eye bolt castings are a valuable addition to any rigging toolkit.

Tips for Properly Installing and Maintaining Stainless Steel G277 Eye Bolt Castings in Rigging Systems

Stainless steel G277 eye bolt castings are essential components in rigging systems, providing a secure anchor point for lifting and securing heavy loads. Proper installation and maintenance of these eye bolt castings are crucial to ensure the safety and efficiency of the rigging system. In this article, we will discuss some tips for properly installing and maintaining stainless steel G277 eye bolt castings in rigging systems.

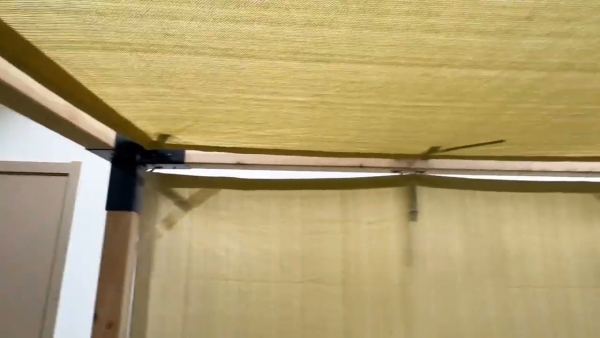

When installing stainless steel G277 eye bolt castings, it is important to ensure that they are securely fastened to a structurally sound anchor point. The eye bolt should be installed at a 90-degree angle to the load to ensure maximum strength and stability. It is also important to use the appropriate size and type of fasteners to secure the eye bolt to the anchor point. Stainless steel bolts and nuts are recommended for use with stainless steel eye bolt castings to prevent corrosion and ensure a secure connection.

Once the eye bolt is properly installed, it is important to regularly inspect and maintain it to ensure its continued safety and reliability. Inspect the eye bolt for signs of wear, corrosion, or damage, and replace it if necessary. It is also important to regularly check the tightness of the fasteners to ensure that the eye bolt remains securely attached to the anchor point.

In addition to regular inspections, it is important to periodically lubricate the threads of the eye bolt to prevent corrosion and ensure smooth operation. Use a high-quality lubricant that is compatible with stainless steel to ensure maximum effectiveness. It is also important to avoid over-tightening the eye bolt, as this can cause damage to the threads and reduce the strength of the connection.

Properly installing and maintaining stainless steel G277 eye bolt castings in rigging systems is essential to ensure the safety and efficiency of the system. By following these tips, you can help prevent accidents and ensure that your rigging system operates smoothly and reliably.